Thermal transfer is a essential principle in multiple areas of scientific study and technology, impacting everything from routine appliances to sophisticated industrial systems. At the center of efficient heat transfer are thermal exchangers, devices designed to enable the transfer of thermal energy between two or more liquids without blending them. These versatile components play a crucial role in improving energy efficiency, managing temperature, and guaranteeing the reliability of numerous applications across varied industries.

In this article, we will examine the details of heat exchangers, delving into their types, designs, and functionalities. We will explain how they operate and underscore the significant impact they have on various sectors, including HVAC systems, energy production, and sustainable energy uses. By understanding the importance of heat exchangers, their maintenance needs, and innovations shaping their evolution, we can appreciate their crucial role in maximizing energy use and supporting sustainability in an ever more energy-conscious world.

Understanding Heat Exchangers

Heat exchangers are crucial devices engineered to conduct heat between two or more liquids while avoiding blending them. These substances may consist of liquids, gases, or an mixture of both, while they typically flow in different paths. The main goal is to effectively absorb thermal energy from a heated liquid and transfer it to a cooler substance, thus maximizing the heat use in various settings. This ability to control thermal conditions makes these devices crucial in many industries and heating, ventilation, and air conditioning systems.

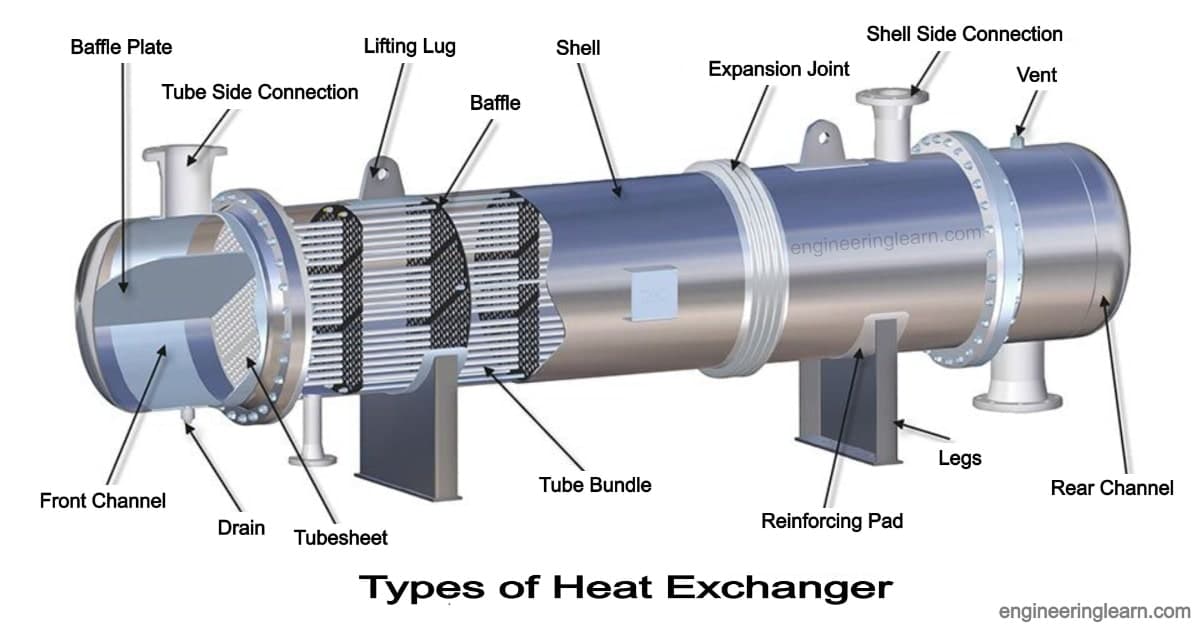

The working principle of a heat exchanger is founded upon the laws of thermodynamics, in which heat naturally flows from a higher temperature fluid to a lower temperature substance until thermal balance is achieved. Heat exchangers are crafted with a variety of structures and materials that improve their heat conductive effectiveness. Typical designs include shell-and-tube, plate-type, and air-cooled types exchangers, each suited for specific applications based on factors like space constraints, fluid properties, and required efficiency.

In the manufacturing world, thermal exchange devices play a crucial role in improving energy efficiency and sustainability. By reclaiming and reusing heat that would otherwise be lost, these devices help lower operating costs and minimize environmental footprint. Their use ranges from power generation and chemical manufacturing to food production industries, illustrating the adaptability and importance of heat exchangers in contemporary engineering. Managing their efficiency and maintenance is essential to ensure longevity and efficacy in those critical applications.

Functions and Effectiveness of Heat Exchangers

Thermal exchangers play a critical role across different industries, serving key functions in processes that require temperature regulation. In Click for more info , they facilitate the transfer of heat between different fluids, ensuring that reactions occur at preferred thermal conditions. In the catering sector, heat exchangers help maintain safety standards by efficiently sterilizing products, thus extending shelf life while retaining taste. Additionally, in electricity generation, they are crucial for controlling the temperature of steam and cooling systems, enhancing overall effectiveness and reliability.

The effectiveness of heat exchangers is strongly linked to their design and the resources used in construction. Different types exist, such as shell and tube, plate-type, and air-cooled type exchangers, each offering distinct performance characteristics suited to particular applications. For instance, plate-type heat exchangers, known for their compact design and high thermal conductivity, are particularly effective in applications where space constraints exist. As industries strive to enhance resource efficiency, advanced designs continue to develop, which improve heat transfer while limiting energy loss.

In addition, the role of heat exchangers in enhancing energy conservation cannot be overstated. By capturing waste heat from industrial processes, they help reduce energy consumption and lower operating costs. This issue is particularly noteworthy in modern energy systems, where sustainability has become a major focus. The incorporation of advanced technologies, such as digital monitoring and intelligent controls, also optimizes the performance of heat exchangers, providing up-to-date data for maintenance and confirming they operate at optimal performance.

Maintenance and Future Trends

Proper care of heat exchangers is vital for ensuring their efficiency and durability. Routine inspections and maintenance procedures are important to prevent fouling, which can significantly hinder performance. Implementing a routine maintenance schedule assists identify initial signs of wear or failure, enabling for timely fixes and reducing unexpected downtime. Employing digital monitoring technologies can also boost maintenance efforts by providing real-time data on heat exchanger performance, making it easier to pinpoint issues before they escalate.

As industries move towards more sustainable practices, future trends in heat exchanger technology are expected to focus on enhanced efficiency and sustainable materials. New developments such as space-saving heat exchangers and advanced designs aim to lower energy consumption and enhance thermal performance. Moreover, the creation of new materials, including composite and organic options, may provide more sustainable alternatives while preserving durability and efficiency in varied applications.

The shift towards renewable energy systems and eco-friendly technologies emphasizes the importance of heat exchangers in facilitating efficient energy transfer and management. In sectors like HVAC, automotive, and chemical processing, current trends include the integration of advanced technologies that boost performance monitoring and predictive maintenance. As industries continue to evolve, the adaptability and efficiency of heat exchangers will play a pivotal role in fulfilling future energy demands and sustainability goals.